We, at PBW, are proud of manufacturing bi-metallic and tri-metallic Bearings, Bushings, Flange Bearings, Flange Bushings, Thrust Washers, Thrust pads, and Thrust and Tilting Pad bearings meeting the highest standards of durability and performance for various applications. Our products are produced using advanced centrifugal casting technology and strips, ensuring superior quality and reliability.

Bimetal Bearing

PBW bimetallic bearings are commonly used in various application including engines, pumps, compressors, and turbochargers to reduce friction between moving parts, Enhanced Wear Resistance, Improved Heat Dissipation, Shock Absorption, Corrosion Resistance, especially in areas where high performance, durability and wear resistance are required. These bearings are designed with two different metals, usually a soft running layer (durable materials according to application) and a hard, wear-resistant supporting layer.

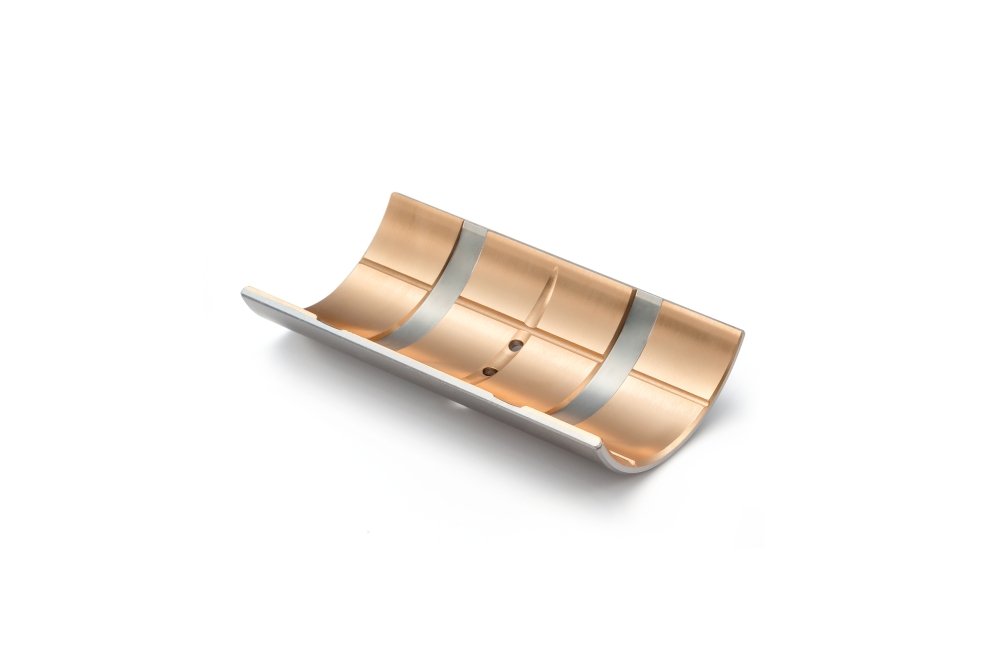

Trimetal Bearing

PBW trimetallic bearings are designed according to the application or customer required material layers, which usually consist of a running layer (soft, anti-friction material) having greater conformability, compatibility, and embeddability , a middle layer (anti-friction material) to provide support to running layer, and a backing layer (hard, wear-resistant material). This design combines the advantages of different materials to provide enhanced performance in demanding applications. The main advantages of trimetallic bearings in applications include excellent wear resistance and increased service life, more evenly distributing the applied load over the surface, reducing the risk of localized wear and damage, protecting the bearing from corrosion and degradation due to exposure to harsh environments, reducing friction with high load capacity, and providing a cost-effective solution in high-speed or high-torque machinery.

Thrust Washers & Pads

PBW thrust washers pads are vital components designed to support axial loads while minimizing friction between moving and stationary parts. These pads play a crucial role in maintaining shaft alignment, preventing unwanted movement, and ensuring smooth operation. By protecting valuable machinery from wear and reducing operational stress, PBW thrust pads are indispensable in various industrial applications where reliability and efficiency are critical.

Journal Bearings

PBW journal bearings are vital components of various drive systems. The key advantages of journal bearings in various applications include reducing friction and wear between moving parts, ideal for supporting rotating shafts under heavy loads, durable and can last the life of the rotation system, provide smooth operation, consistent rotation for critical components, enhancing the performance and efficiency.

Flange Bearings

PBW Flange Bearings, including flange bushings and flange half bearings, are designed for superior axial and radial load support, ensuring secure positioning, easy installation, and long-lasting stability. Their integrated flange design enhances alignment, reduces vibration, and optimizes performance across automotive, construction, marine, and industrial machinery. With customized solutions, high-performance materials, and advanced engineering, PBW Bearings offer exceptional durability, minimal maintenance, and maximum efficiency.

Bimetal Bushing

PBW bimetallic bushings are commonly used in various application including engines, pumps, compressors, and turbochargers to reduce friction between moving parts, Enhanced Wear Resistance, Improved Heat Dissipation, Shock Absorption, Corrosion Resistance, especially in areas where high performance, durability and wear resistance are required. These bushings are designed with two different metals, usually a soft running layer (durable materials according to application) and a hard, wear-resistant supporting layer.

White Metal Bearings

PBW Babbitt bearings are widely used in applications where high load-bearing capacity, low friction, and durability are essential. The bearings are made from a soft composite alloyed metal (tin & lead based )called Babbitt metal. Babbitt materials offer exceptional conformability, compatibility, and embeddability to the shaft surface, reducing wear and preventing damage to both the bearing and the shaft. The key advantages of babbitt bearings in engine applications include self-lubricating, shock absorption, load distribution, galling resistance.