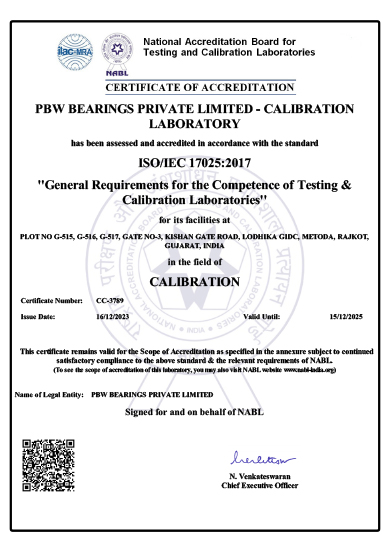

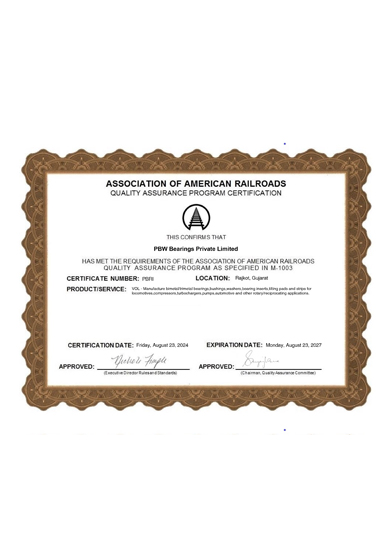

Our Commitment to Excellence

We are committed to delivering the highest quality products to our customers. Our manufacturing processes follow strict quality control measures, and our products undergo rigorous testing to ensure they meet or exceed industry standards. Our team of experienced engineers and technicians continuously works towards improving our products’ performance and reliability, providing our customers with peace of mind and confidence in the quality of our products.