BACKGROUND IMAGE BLOCK

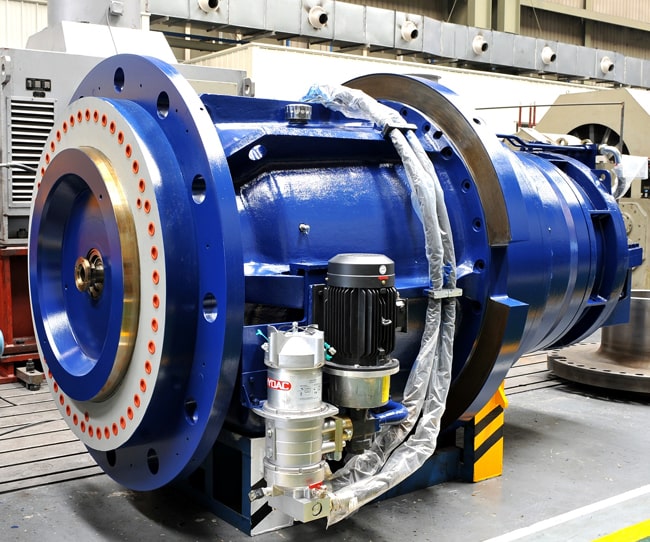

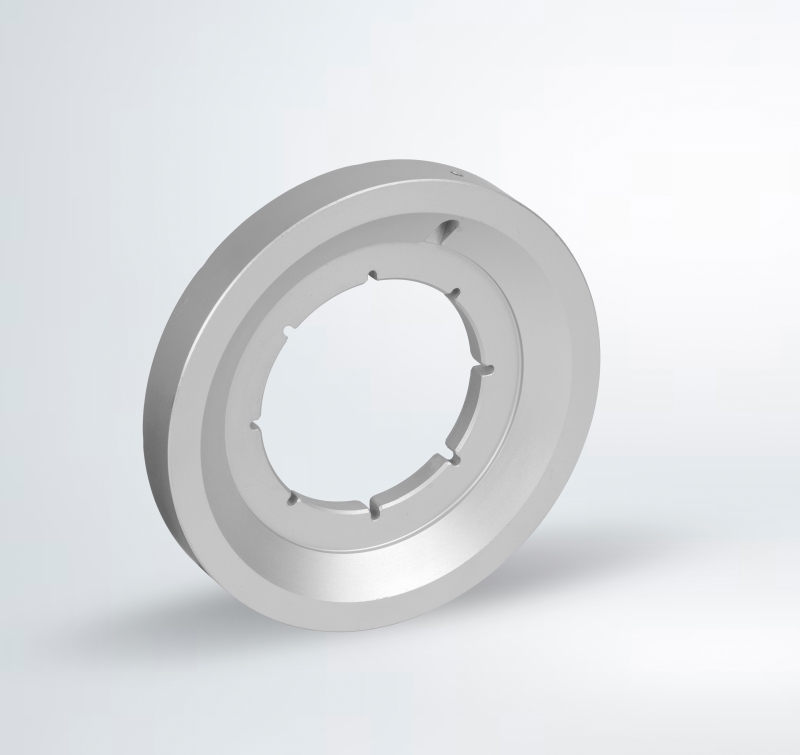

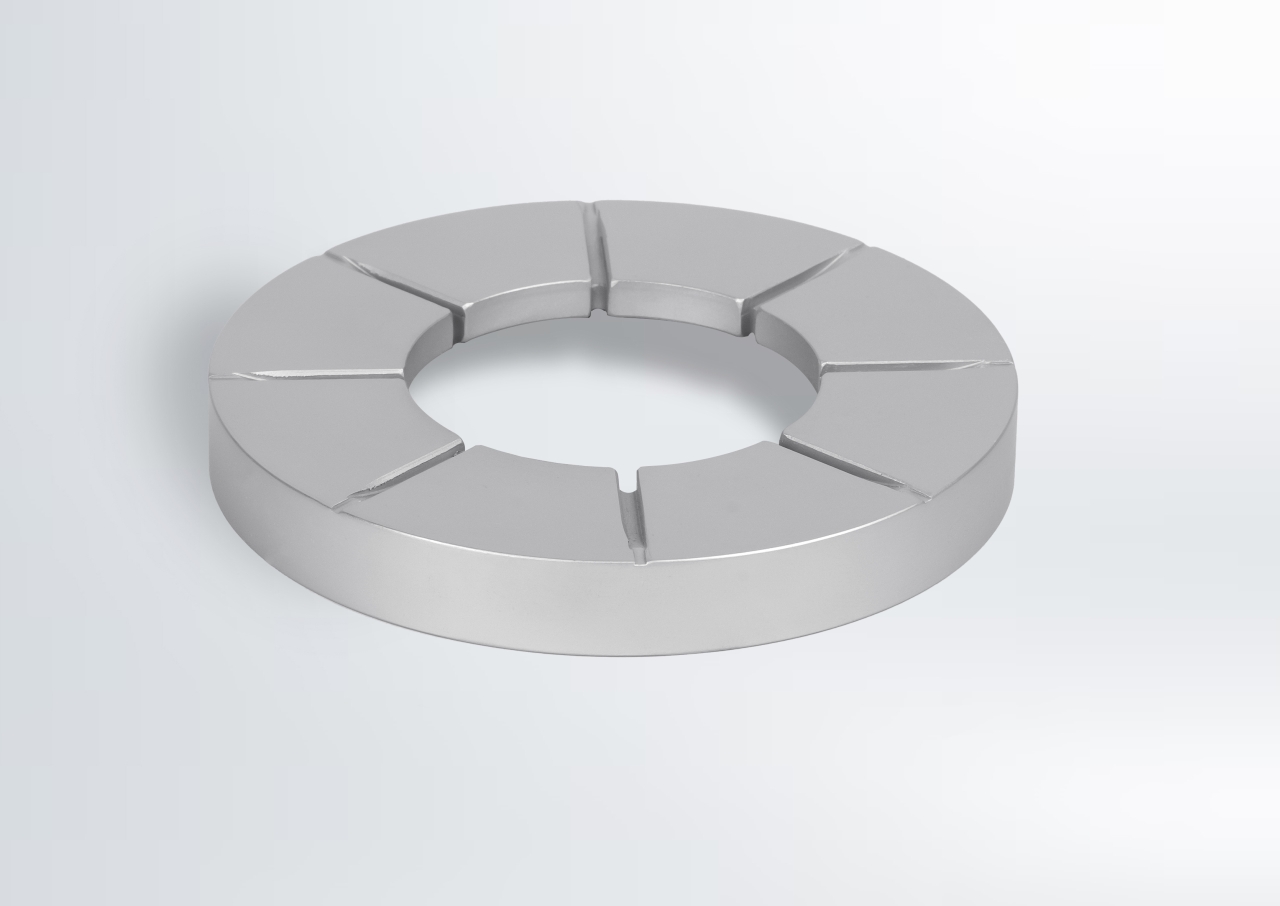

PBW thrust washer bearings are vital components designed to support axial loads while minimizing friction between moving and stationary parts. These bearings play a crucial role in maintaining shaft alignment, preventing unwanted movement, and ensuring smooth operation. By protecting valuable machinery from wear and reducing operational stress, PBW thrust washers are indispensable in various industrial applications where reliability and efficiency are critical.

PBW thrust washers are available in a variety of materials tailored to meet specific operational needs, including bronze, plug graphite, and self-lubricating PTFE. Bronze thrust washers, widely used for their strength and wear resistance, help safeguard underlying components from damage. To enhance lubrication and reduce friction, these washers can be customized with grooves that distribute lubricant effectively. In high-heat environments, these grooves can be filled with graphite, providing self-lubricating properties and significantly extending the lifespan of the bearing.

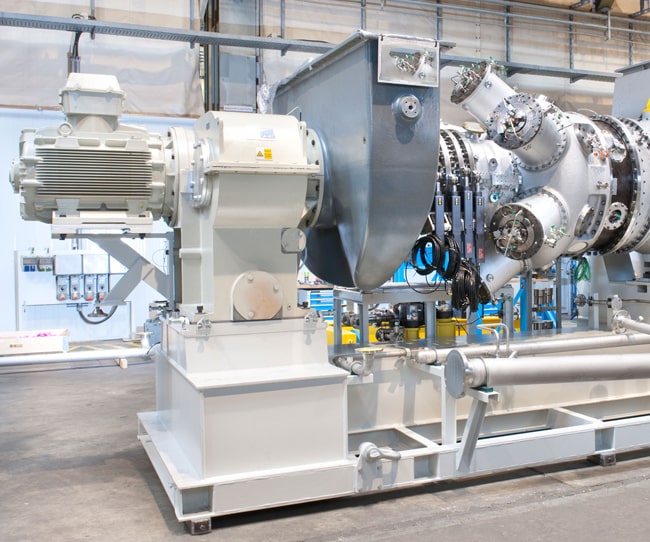

When paired with PBW thrust tilting pad bearings, thrust washers improve the overall performance of rotating machinery, especially in applications subjected to heavy axial loads. This combination of components enhances reliability, minimizes maintenance requirements, and ensures consistent performance in demanding environments. The integration of thrust washers with tilting pad bearings offers superior load-bearing capacity and ensures smooth operation even under intense conditions.

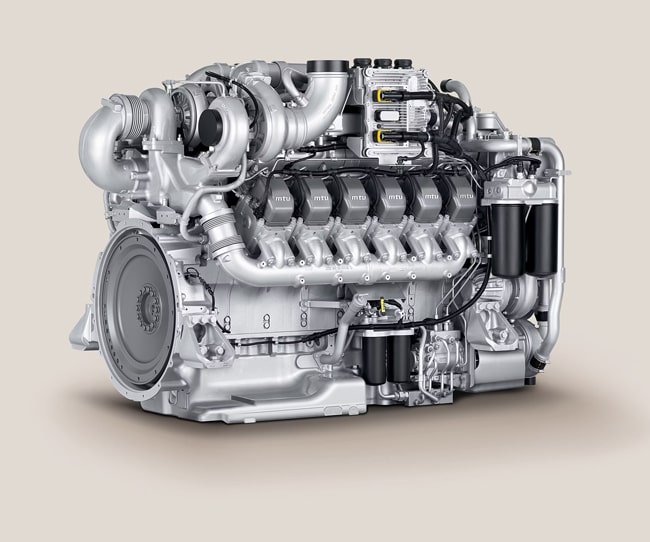

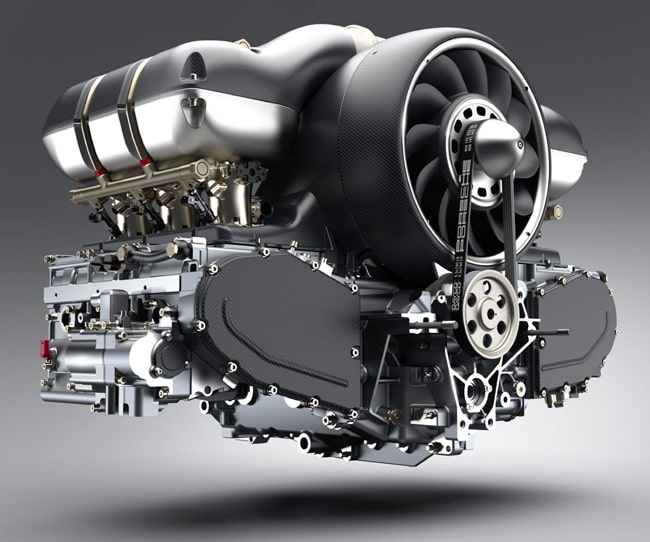

With their robust design, PBW thrust washer bearings provide long-lasting durability and reliable performance, reducing downtime and maintenance costs. They are a cost-effective solution for industries that require high performance under heavy axial loads. Whether in automotive, manufacturing, or other high-demand sectors, PBW thrust washers are engineered to deliver optimal functionality, ensuring your machinery runs smoothly for extended periods while minimizing wear and tear.